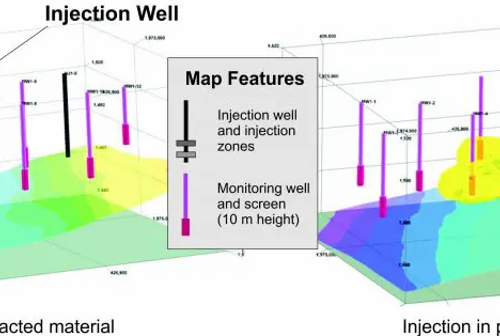

Once the target zone is confirmed the next step is to proceed with the well installation in the leach pad and to install the cyanide injection wells, the wells have a perforated screen at the designed length set by client’s specifications.

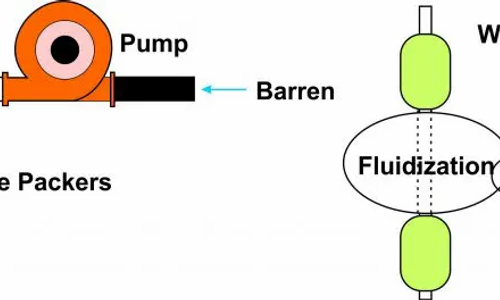

The casings allow the borehole to stay intact, as an upper and lower k-packer are installed at specific depths to direct the cyanide solution at targeted areas and depths with in the borehole.

This process is repeated on an eight-week cycle with four weeks of solution and four weeks of rest. Once the cycle is completed, the k-packers inside the perforated screen are moved to a new depth. The well would receive the solution at three heights, targeting the bottom, middle, and top.