RC drilling uses a drill bit that features round, protruding tungsten-carbide buttons, to cut through hard rock and earth. The drill rods themselves are hollow and feature an inner tube with an outer barrel (similar to air core drilling).

A pneumatic reciprocating piston (also known as a downhole hammer) delivers rapid impacts to the drill stem, transferring this energy through the drill bit. This extra concussive force hammers the bit into the rock, pulverising it, while a rotational device ensures that the drill bit hits new sections of rock with each impact.

Inside the drill bit, a dual-walled drill pipe is used to achieve circulation, with compressed air getting injected between the tubes to flush the cuttings from the hole and up through the inner tube. The cuttings travel back up the tube to the surface, into a cyclone, where they go over a splitter that delivers the samples into a sample bag.

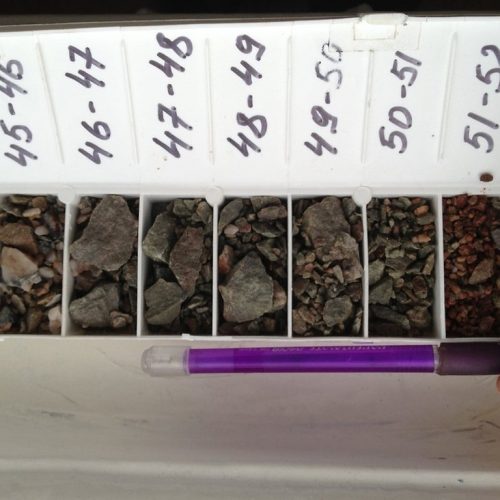

The exploration team then collects the samples, align them to the hole depth, and layout for their client to log. From here the sample is transported to their lab for assay.

RC drilling typically produces dry cuttings, as their compressors also pump air ahead of the drill bit, drying the rock in the process.

While the process itself is typically dry, water can be injected when collaring a new hole as a way to reduce dust and assist in lifting cuttings to the surface. When water is injected, an additive gets mixed into the water, known as Super Foam. This makes the cuttings bind to each other, increasing sample recovery.